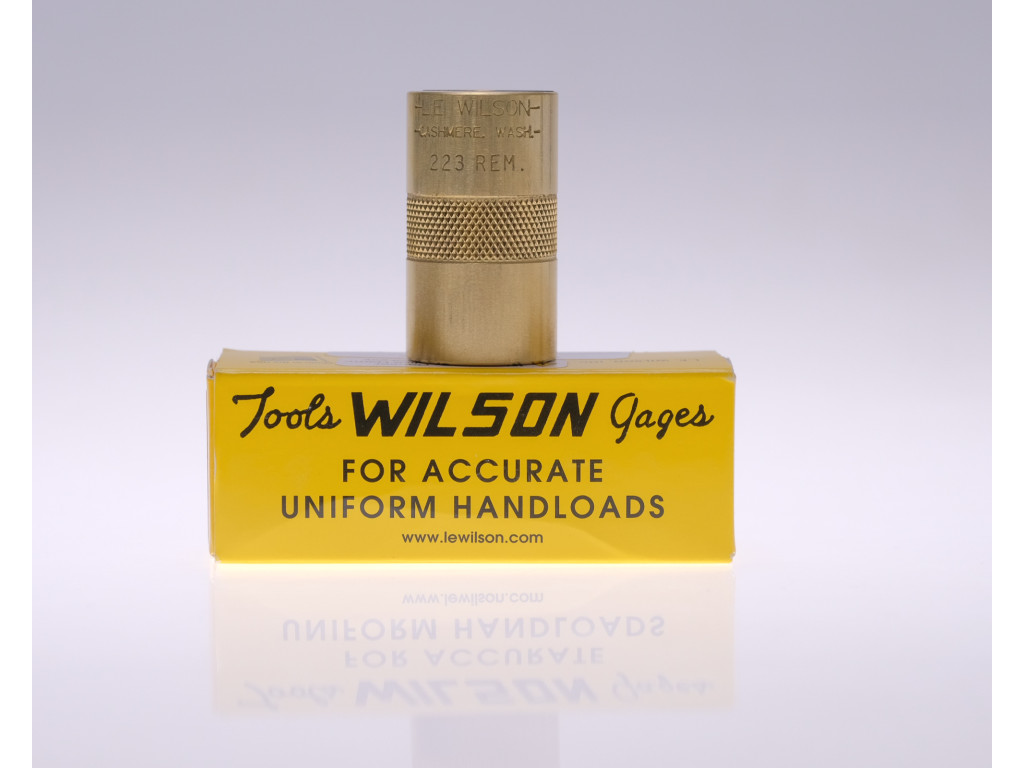

One piece gauge will check overall length to indicate the need for trimming, datum to head length to assure correct headspace and prevent oversizing. The Cartridge Case Gage was designed with safety in mind and was invented by our founder Sam (L.E.) Wilson in 1935 after a fellow shooter approached him for help in solving a case-separation issue. The gauge allows you to see just how much you are sizing back your shoulder on your cases.

This is best done by following the steps below.

Measure a case in AS-FIRED condition. Note headspace measurement

Resize case on current die setting

Then place back in the gage to see just how much you are sizing the shoulder back. This can be measured by using the Case Gage Depth Micrometer Finally, adjust the sizing die accordingly to the desired shoulder setback.

After sizing your cases, there is a good chance the brass will lengthen. The gauge will also check the min/max case length and point out the need for case trimming. This is an essential tool for every reloader.

Note: Does not measure body diameters. This gage is intended to be used with fired cases to determine a basis for full-length sizing and trimming.

Part Number: CGB-CGB-223R

For more information visit: https://lewilson.com/brass-case-gage

![GB Ammunition, 12-Guage, 34 gr #AAA Express [25] GB Ammunition, 12-Guage, 34 gr #AAA Express [25]](https://images.bellumarcus.co.za/image/cache/catalog/Ammunition/DSCF9507-300x300.jpg)